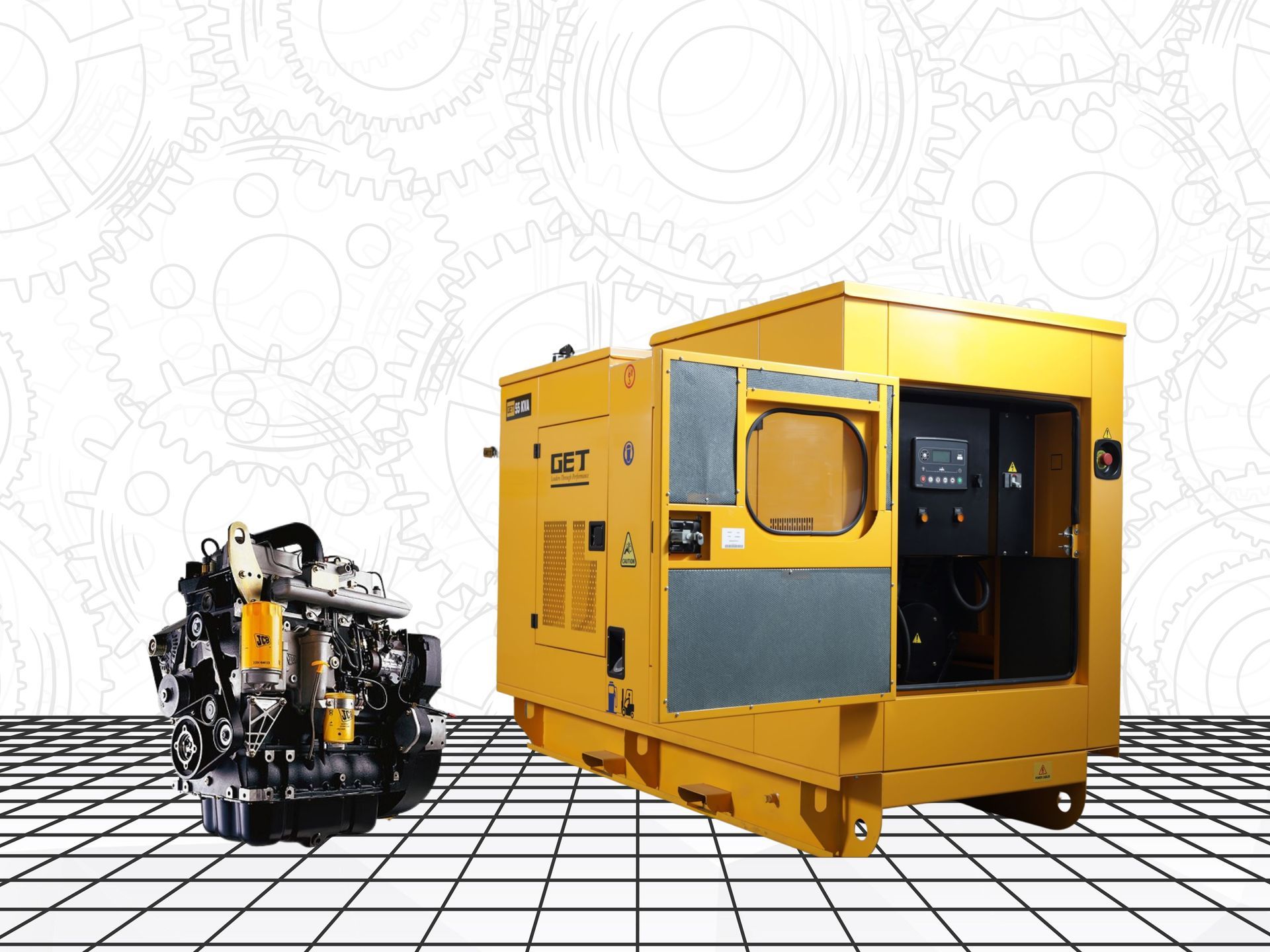

ENCLOSURES OF SILENT / SOUNDPROOF GENERATORS

A soundproof generator, soundproof container, or silent generator are terms that many people are familiar with. Few people, though, are aware of how they operate or what to anticipate from them unless they are employed in the field.

The operation of a soundproof container

Generators are very noisy, particularly those that are not containerized. They are so loud that working close to them can result in hearing loss unless protective gear is worn, and they are so noisy that they pose a serious risk to surrounding businesses and bystanders. Therefore, to ensure that any portable or emergency power generators only produce an acceptable level of noise, laws and regulations have been passed. A silent generator reduces noise that is audible to customers, staff, and other members of the public by operating inside a soundproof container or generator enclosure.

What a soundproof Generator Enclosure contains?

The majority of silent generators or soundproof containers are made of composite materials in their generator enclosures. Usually, there are two types of materials used for this purpose: hard layers that reflect sound energy into the enclosure and soft, porous, resilient layers that absorb sound energy and turn it into heat. However, different materials absorb different frequencies more or less effectively. It's possible that "Material A" absorbs very high frequencies very well but poorly at lower ones. "Material B" may be excellent at absorbing low to midrange frequencies, but it is ineffective at high frequencies. For this reason, the majority of contemporary soundproof generators employ multiple layers of various materials. Highly porous materials work best at absorbing higher-frequency sound because they can send these smaller waves deep into the material, dispersing and absorbing them. The challenge of lower-frequency sound is completely different. Sometimes, large, heavy layers of material that are merely resistant to movement can deflect or absorb these waves; however, when working with lightweight materials, an "air pocket" technique yields the best results. Large, shallow air gaps separate the thin material panels. This arrangement raises the low-frequency sound to a higher, sharper pitch by using the resonance effect. The porous materials in the air gap itself can then absorb that higher-frequency sound. Since not all generators produce the same frequency range, the specific materials and layering techniques used will vary depending on the generator. For the soundproof container to be as effective as possible at absorbing the precise range of sound that the gen-set produces, a generator enclosure should be engineered for a specific class and type of generator, or better yet, a specific model.

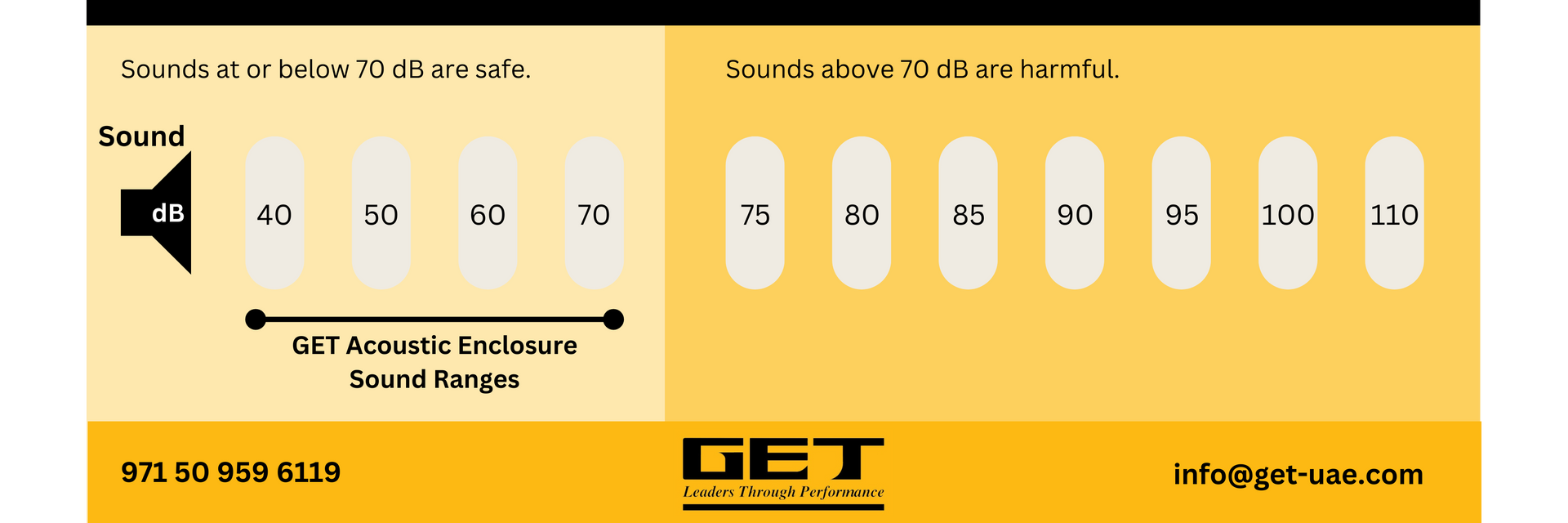

GENERATOR NOISE - HOW IS IT QUANTIFIED?

Decibels (dB) are commonly used to measure sound levels. Loud is generally defined as anything over 80 dB. Most people find sound levels between 100 and 125 dB to be "uncomfortable," and beyond 140 dB, most people experience pain. There are two ways to measure the noise produced by a generator: either on an audible scale (dB(A) that only really considers sounds that human ears can normally detect, or on a linear scale (dB(L) that weights all frequencies equally. dB(A) is the most useful scale to use for a soundproof container

How effective is a soundproof container in reducing diesel generator noise?

Naturally, there is a gap between the amount of noise reduction that can be achieved commercially and the amount that can be achieved theoretically. The consensus is that the maximum feasible reduction for a prefabricated soundproof container is 40 dB(A). Our decades of experience, however, enable us to achieve larger reductions if necessary; however, additional cost, weight, and installation challenges may render this unfeasible for certain applications.

Which enclosure is optimal for my generator?

In short, speak with our professionals! Contact us by email at info@get-uae.com or by phone at +971 50 959 6119. We would be pleased to go over your needs and the specifics of the project in detail.

Click to Share