March 4, 2024

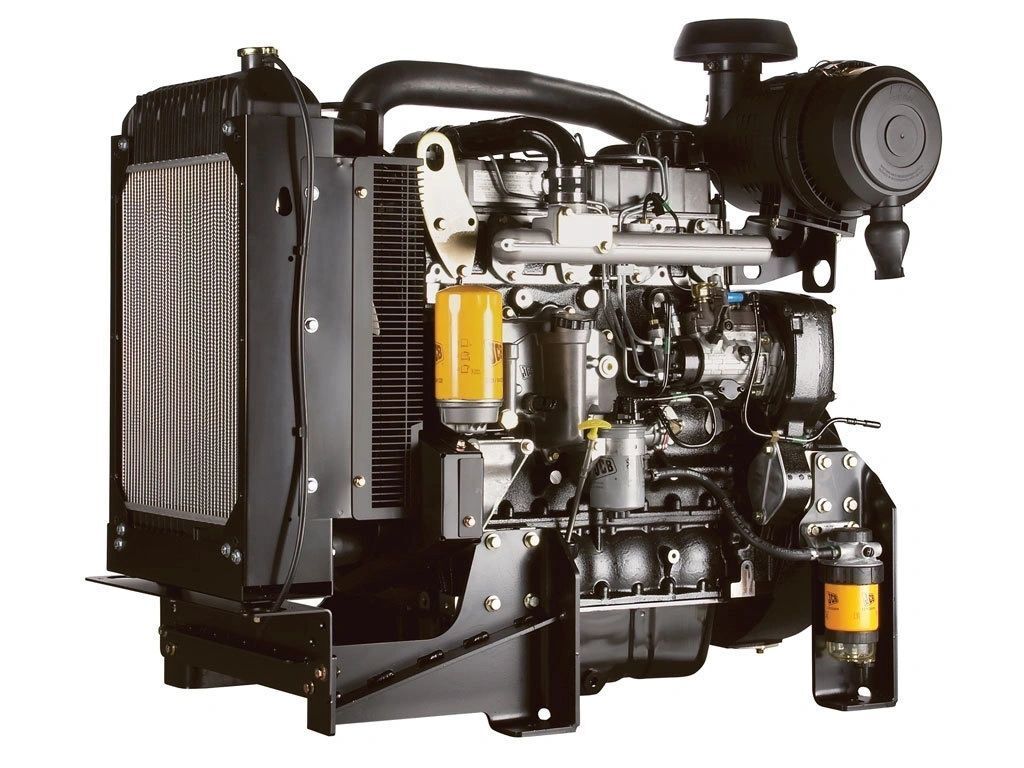

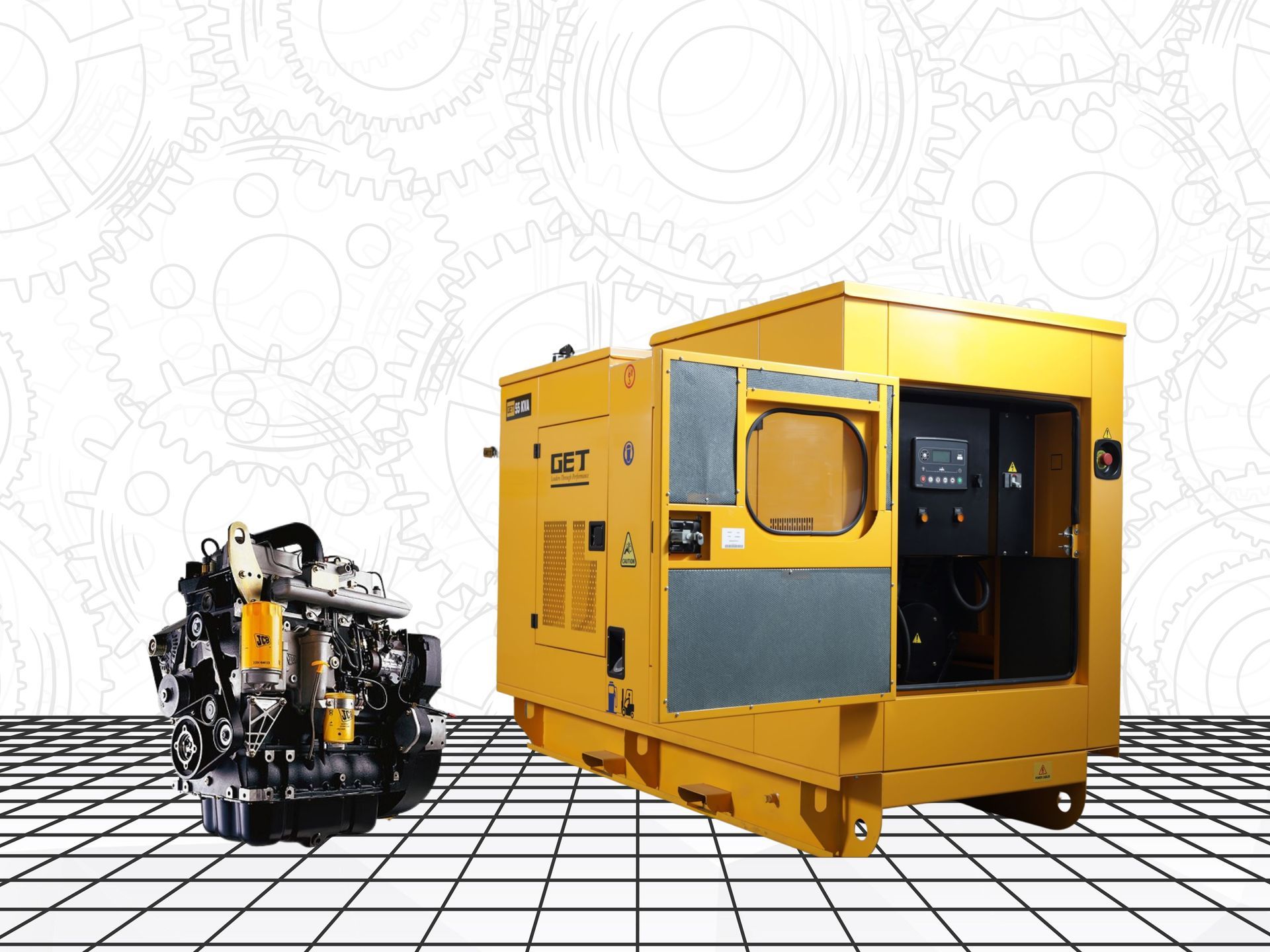

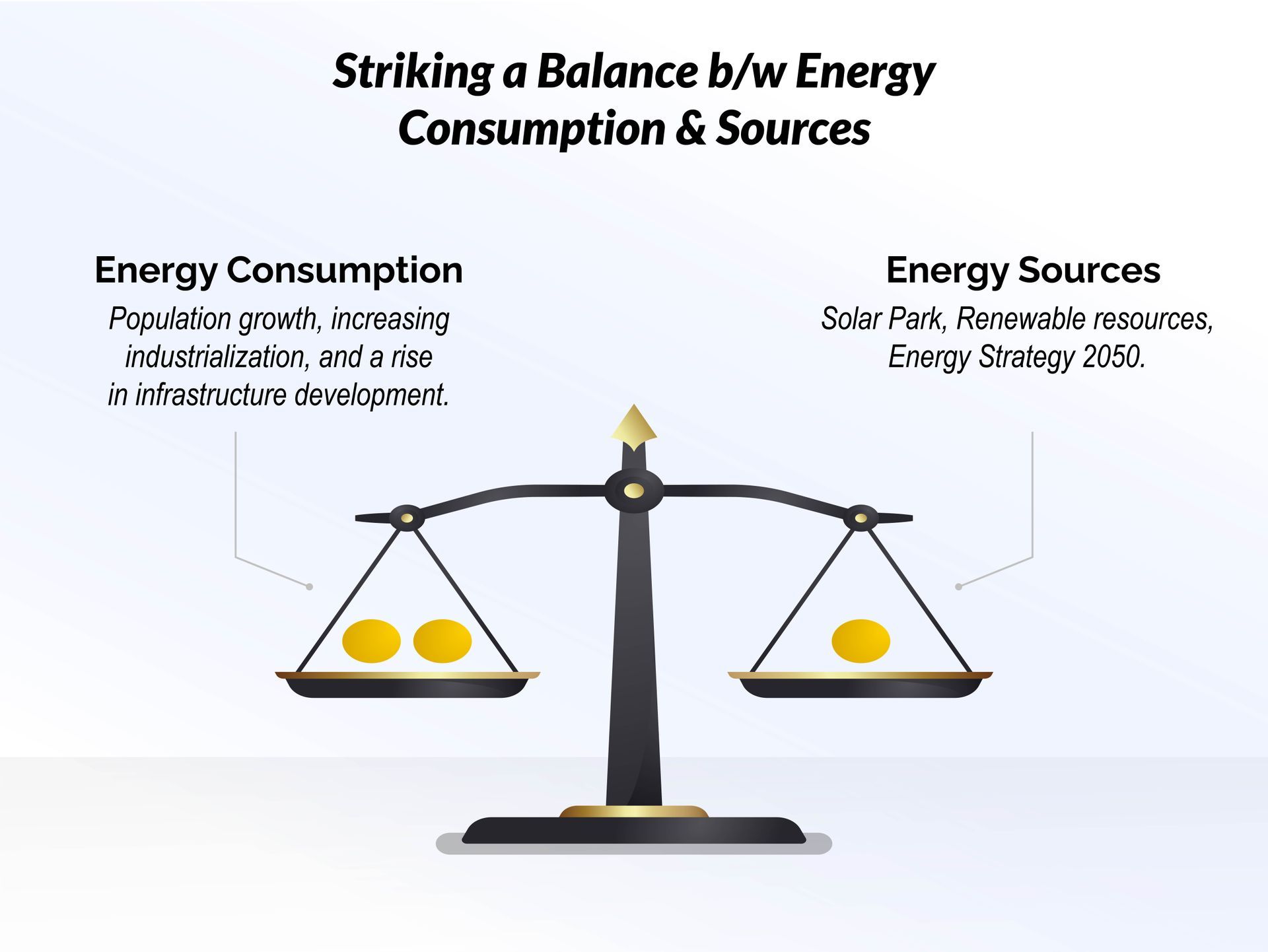

In recent years, the United Arab Emirates (UAE) has experienced a significant surge in the demand for power generators. This uptrend can be attributed to various factors, including rapid urbanization, industrial growth, extreme weather conditions, growth in tourism, a shift to renewable energy, and the need for reliable backup power sources. Let's delve deeper into the reasons behind this increasing demand and understand the relevant data and statistics shaping this market trend. 1. Urbanization and Infrastructure Development As urban centers in the UAE continue to expand and develop, the electricity demand has risen exponentially. With the construction of mega-projects, high-rise buildings, and smart cities, the strain on the existing power grid has intensified. This has led to a growing reliance on power generators to supplement the grid during peak demand periods or in areas with inconsistent power supply. The bustling cities of Dubai and Abu Dhabi, along with other emirates, have witnessed tremendous economic growth and urban development. These monumental advancements have led to a surge in residential, commercial, and industrial construction projects. As electricity remains the backbone of these endeavors, the demand for power generators continues to rise. According to the International Monetary Fund (IMF), the UAE's GDP has grown at an average rate of 3.8% from 2016 to 2020, indicating a sustained economic expansion. 2. Industrial Growth and Commercial Sector The UAE's thriving industrial and commercial sectors have also fueled the demand for power generators. Industries such as manufacturing, oil and gas, construction, and logistics require a stable and uninterrupted power supply to operate efficiently. Power generators serve as a reliable backup solution to ensure continuous operations, safeguarding businesses from costly downtime and losses. The construction sector alone generated a staggering AED 38.4 billion ($10.5 billion) in value in 2019, accounting for 7% of the UAE's GDP. 3. Extreme Weather Conditions and Resilience The UAE is known for its extreme weather conditions, including scorching summers and occasional sandstorms. These environmental challenges pose risks to the stability of the electrical grid, leading to power outages. To mitigate these risks, many businesses, communities, and infrastructure projects have turned to power generators as a primary or backup power source to maintain operations and critical services during adverse conditions. The UAE's desert climate exposes the region to extreme weather conditions, with scorching summers reaching temperatures above 45°C (113°F). This excessive heat increases the strain on the power grid, resulting in frequent power outages. To combat this, both businesses and individuals have turned to power generators to ensure continued operations and prevent disruptions caused by erratic electricity supply. According to the World Bank, average annual temperatures in the UAE have increased by approximately 1.15°C (2.07°F) over the last 50 years, further intensifying the need for power generators. 4. Growth in Tourism and Hospitality The UAE is a top tourist destination, attracting millions of visitors each year. From luxury resorts to extravagant shopping malls, the tourism and hospitality sectors have flourished, placing significant demands on the local power supply. Resorts, hotels, and tourist attractions all require uninterrupted power for their guests' comfort and safety, driving the demand for power generators. According to the UAE Ministry of Economy, the tourism sector contributed approximately AED 164.7 billion ($44.9 billion) to the national economy in 2019, accounting for 11.1% of the UAE's overall GDP. 5. Shift towards Renewable Energy While the surge in demand for power generators might seem counterintuitive amid the global shift towards renewable energy, it serves as a transitional necessity. The UAE is also actively investing in renewable energy sources like solar and wind power. However, the integration of such sources into the national grid takes time and careful planning. Power generators serve as a reliable stop-gap solution until renewable energy infrastructure is fully developed. The UAE aims to generate 50% of its energy from clean sources by 2050, as announced by its leadership under the "UAE Energy Strategy 2050." Conclusion: Embracing a Resilient Energy Future The growing demand for power generators in the UAE is a clear indicator of the country's commitment to building a resilient and sustainable energy infrastructure. As the need for a reliable power supply continues to rise, the use of power generators will play a crucial role in enhancing energy security, promoting economic growth, and ensuring uninterrupted access to electricity for all sectors of society. By staying attuned to market trends, leveraging innovative technologies, and embracing energy-efficient solutions, the UAE is poised to meet the escalating demand for power generators while advancing towards a more resilient and sustainable energy future.